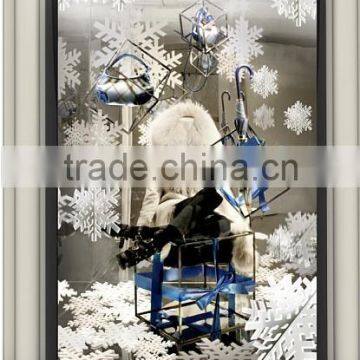

Customized window decorative cutting snowflake for Christmas

USD $0.5 - $2

/ Piece

1000 Pieces(Min.Order)

- Yantian Shenzhen

- Credit Card

You May Like

Product Details

| Place of Origin | Guangdong, China | Model Number | Customized | |

| Plastic Modling Type | Mould |

Product Description

Vacuum forming plastic product productive process.

1.Extruding plastic sheet:ABS, HIPS, PP, PE, PC, PETG, PMMA resin granules are extruded or co-extruded into thermoplastic sheet--textured, smooth, gloss or matt, fire-retarded or UV resisted

2.Vacuum forming to shape: After being heated, the plastic sheet is stretched onto or into a mould, and held against the mold by applying vacuum between the mould surface and the sheet to form desired shapes.

3.Cooling to maintain shape: Once formed the plastic need to cool before being released from the mould. To speed up the cooling cycle, fans are fitted and activated once the plastic part is formed.

4.Making large product:Our machine could be restructured to make larger plastic ABS thick vacuum forming plastic shell, with maximun dimensions of 3000*1800*1000* (L*W*H*T)

5.Trimming edges: Extra material is firstly trimmed before more accurate processing. Sawing is often used in this stages. Polishing is made additioanlly to smoothen the edges.

6.Drilling holes: Drilling oftens follow the trimming. Other post forming processes include decoration, printing, strengthening, reinforcing and assembly.

7.CNC Processing: For more accurate and faster speed post thick ABS vacuum forming plastic shell processing, CNC is often used. The machine is computer programmed to select the correct cutting tools and angle to suit each cutting area.

8.Examination and checking: Before packaging, all our thick vacuum forming samples and products will be carefully checked in terms of dimensions, surface finish, stenghth, colour requirements and so on.

9.Cleansing and Packaging All ABS thick vacuum forming plastic shells are cleaned before packaging. Products are wrapped with plastic film to prevent scratches and cartoon boxs are used or other methods are applied as required.

Buying Guides

1)Customers provide 3D design drawing or sufficient info ( leng x widht x highx thickness, material, colors etc)

2)We offer quotation in time

3)Once confirmed price,we arrange to build mold according to customer's design drawing

4)Make samples for customer approved

5)Arrange mass production after sample approved by customers

6)Timely complete production for on-time delivery

1.Extruding plastic sheet:ABS, HIPS, PP, PE, PC, PETG, PMMA resin granules are extruded or co-extruded into thermoplastic sheet--textured, smooth, gloss or matt, fire-retarded or UV resisted

2.Vacuum forming to shape: After being heated, the plastic sheet is stretched onto or into a mould, and held against the mold by applying vacuum between the mould surface and the sheet to form desired shapes.

3.Cooling to maintain shape: Once formed the plastic need to cool before being released from the mould. To speed up the cooling cycle, fans are fitted and activated once the plastic part is formed.

4.Making large product:Our machine could be restructured to make larger plastic ABS thick vacuum forming plastic shell, with maximun dimensions of 3000*1800*1000* (L*W*H*T)

5.Trimming edges: Extra material is firstly trimmed before more accurate processing. Sawing is often used in this stages. Polishing is made additioanlly to smoothen the edges.

6.Drilling holes: Drilling oftens follow the trimming. Other post forming processes include decoration, printing, strengthening, reinforcing and assembly.

7.CNC Processing: For more accurate and faster speed post thick ABS vacuum forming plastic shell processing, CNC is often used. The machine is computer programmed to select the correct cutting tools and angle to suit each cutting area.

8.Examination and checking: Before packaging, all our thick vacuum forming samples and products will be carefully checked in terms of dimensions, surface finish, stenghth, colour requirements and so on.

9.Cleansing and Packaging All ABS thick vacuum forming plastic shells are cleaned before packaging. Products are wrapped with plastic film to prevent scratches and cartoon boxs are used or other methods are applied as required.

Buying Guides

1)Customers provide 3D design drawing or sufficient info ( leng x widht x highx thickness, material, colors etc)

2)We offer quotation in time

3)Once confirmed price,we arrange to build mold according to customer's design drawing

4)Make samples for customer approved

5)Arrange mass production after sample approved by customers

6)Timely complete production for on-time delivery

Welcome to inquiry!

Contact Us

- Shenzhen Zhenrong Plastic Co., Ltd.

- Contact nameKevin zhou Chat Now

- Phone86-769-86435006

- AddressB building, No. 1 LianTangJiao Industry, ShiMa Village, Tangxia Town, DongGuan City, China, Dongguan, Guangdong

Product Categories

New Products

-

Thick Vacuum Forming mask

-

large plastic display

-

large plastic vacuum forming parts

-

large plastic vacuum forming cover

-

ABS Vacuum Forming plastic cover

-

Vacuum Forming plastic cover

-

Vacuum forming plastic inner liner door for refrigerator

-

ABS vacuum forming refrigerator inner liner

-

custom vacuum forming plastic refrigerator door shelf liner

-

Plastic machine parts

-

Plastic vacuum forming products

-

Newly vacuum forming plastic parts

Popular Searches

- ABS

- plastic material

- Material Abs

- Flame Retardant Abs

- Flame Retardant Fr Abs

- Plastic Granules Abs

- Resin Abs

- Recycled Abs

- Plastic Material Abs

- ketone resin

- chemical filling

- abs plastic

- nylon pa66

- chemical materials

- pvc resin

- cpp

- frp profile

- raw material

- Chemical Raw Material

- plastic goods

- expandable polystyrene

- eps resin

- expanded polystyrene

- flame retardant eps bead

- polystyrene

- eps raw material

- rubber granules

- pom

- cpvc

- frp pipe

Recommended Products

- South American Rain Boot Shoe Making PVC Material Compounds Granules for Plastic Shoes Sole

- Rain Boots Polyvinyl Chloride (PVC) Material Compound Granules Pellets for Shoe Industry in Africa Market

- Flexible PVC Compounded Granules for Kids Sandal Slipper Production PVC Pellets for Shoes Making in Africa Market

- White Grey PVC Compound Granules Injection Grade for Sewage Pipe Fittings Applications

- Wholesale PVC Compound Pellets Colorful Soft PVC Granule for Shoes Sole

- White Grey PVC Compound Granules Injection Grade for Molding for Sewage Pipe Fittings

- U-Trough Liners, UHMWPE Two layers

- UHMWPE scraper blade, custom made

- YS-071S Glove Chemical Penetration Tester

- YS-072S Glove Water Impermeability Tester

- YS16B Thermal Aging Test Chamber

- Paletas transportadoras de arrastre de UHMW

Find Similar Products By Category

- Chemicals > Plastic Products > Other Plastic Products

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Shenzhen Zhenrong Plastic Co., Ltd.

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

Kevin zhou

Hi there! Welcome to my shop. Let me know if you have any questions.

Kevin zhou

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile